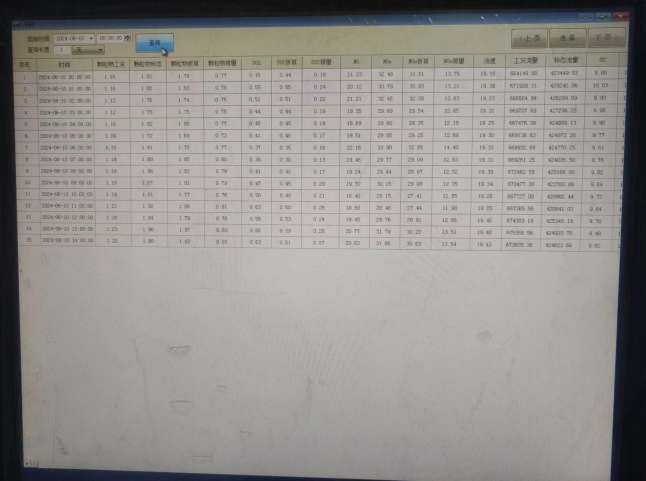

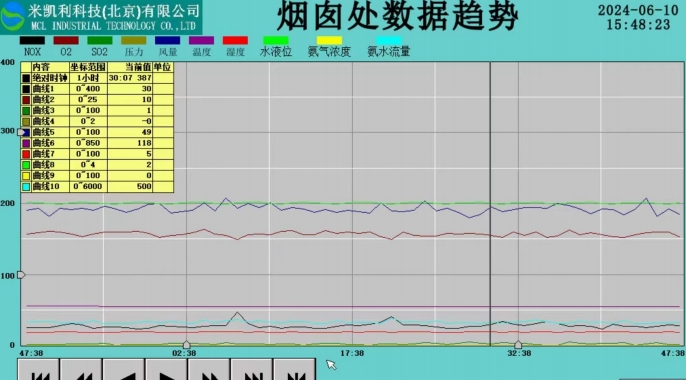

Recently, our company has successfully completed the 72-hour performance test in the Xinjiang denitrification ultra-low emission renovation project. NOx is stably controlled within 50 mg, the ammonia consumption per ton of clinker is 2.9 kg, the denitrification efficiency reaches 93%, and the system runs smoothly! The achievement of this result not only reflects the company's technical strength in the field of environmental protection, but also demonstrates my country's remarkable achievements in the research and development and application of environmental protection technologies.

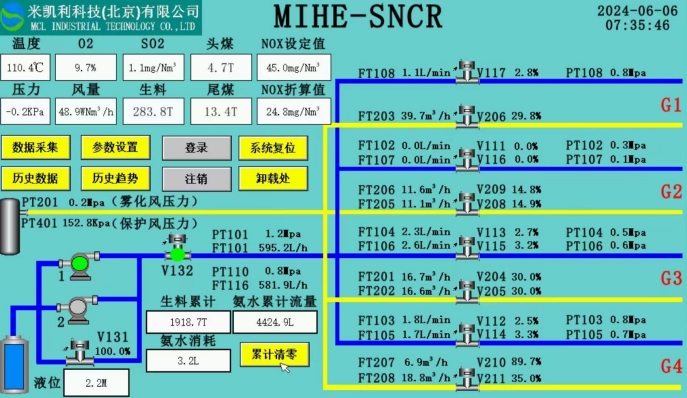

As an enterprise adhering to the concept of social responsibility and environmental protection, our company has always regarded meeting customer needs as its top priority and has always been committed to providing customers with the best services and the most professional solutions. In the field of denitrification technology, our company has successfully developed intelligent and efficient denitrification (MIHE-SNCR) technology with independent intellectual property rights after nearly ten years of technical research and development and more than four years of project practice.

This technology has reached the international leading level after continuous optimization and improvement. In many practical application projects, MIHE-SNCR technology has demonstrated excellent performance and excellent operation results. Not only is it significantly lower than the newly promulgated national NOx emission and ammonia consumption requirements, but its performance indicators also surpass those of domestic and foreign counterparts. This fully demonstrates my country's innovation ability and competitiveness in the field of environmental protection technology, and has also made important contributions to the development of my country's environmental protection cause.

MIHE-SNCR Denitrification technology has the following technical advantages:

1. Achieve non-catalytic denitration efficiency of more than 90%, up to 95%.

2. The denitration efficiency in cement plants is equal to or greater than the comprehensive denitration efficiency of ordinary SNCR+SCR.

3. Under the same emission indicators, the amount of ammonia water is lower.

4. NOx emission indicators are achieved or even better than SCR emission indicators.

5. NOx emissions can be stably controlled below 50mg.

6. The investment cost is lower than SCR denitration technology.

7. The construction period is short and the kiln can be transformed without stopping.

8. It will not cause waste heat power generation to reduce production.

9. The operating cost is low, and the annual operating cost is more than 5 million yuan lower than SCR denitration. 10. No catalyst hazardous waste is generated, and there is no secondary pollution. If all cement plants in the country adopt our company's intelligent and efficient denitration (MIHE-SNCR) technology, 50,000 cubic meters of SCR catalyst hazardous waste can be reduced each year, which is of great significance to environmental protection. In the future, our company will continue to adhere to technological innovation, provide customers with more efficient denitrification solutions with more advanced technology and more professional services, and help the development of my country's environmental protection cause. At the same time, we also look forward to working hand in hand with the majority of owners and partners to contribute to my country's environmental protection cause.