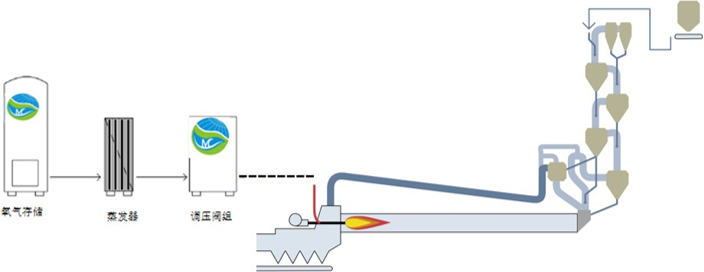

Pure oxygen and oxygen-enriched combustion technology

Pure oxygen and oxygen-enriched combustion have significant energy-saving effects, effectively extending the life of the kiln, which is beneficial to improving product output and quality, reducing flue gas emissions, increasing the CO2 concentration in flue gas, and reducing the primary investment and operating costs of carbon capture.

Advantage:

5-20% increase in productivity

3-15% energy savings

Up to 40% increase in secondary and waste-derived fuels (liquid and solid), lower fuel costs

Reduce emissions (NOx, CO)

Improve cement quality/fuel burn rate

One-stop solution, easy to retrofit in existing facilities

Low CAPEX, easy to maintain

The role of oxygen-enriched and pure oxygen combustion:

1. Increase flame temperature

2. Accelerate combustion speed and promote combustion safety

3. Reduce the ignition temperature of fuel and reduce burnout time

4. Reduce excess air coefficient and reduce flue gas volume after combustion

5. Suitable for both new boilers and renovation of old boilers

6. The NOx content generated after combustion is significantly reduced

7. Increase CO2 concentration in flue gas by 1-4 times