Hazardous waste disposal solutions

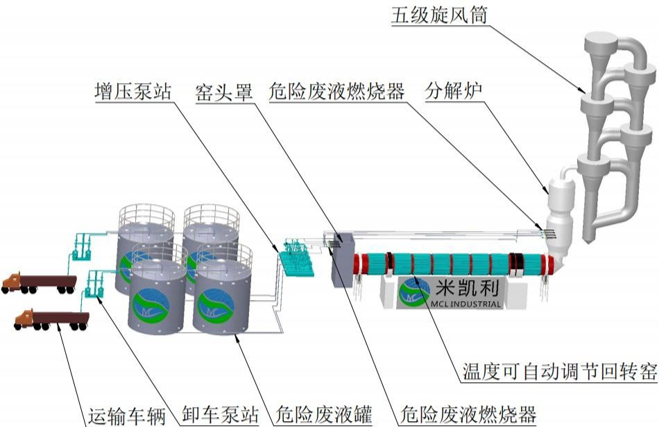

The hazardous waste liquid has complex components. After being mixed and neutralized, it is classified and transported to various storage tanks. The storage tank needs to be treated with anti-corrosion lining to resist the corrosion of harmful substances in the hazardous waste liquid. The tank area is designed according to explosion-proof requirements, and the instruments and motors are configured according to explosion-proof standards.

The waste liquid in the waste liquid storage tank is pressurized by the pneumatic booster pump station and sent to the waste liquid burners at the head and tail of the kiln. After being fully atomized by our patented hazardous waste burner, it is sent to the rotary kiln and decomposition furnace for incineration. The flue gas generated after incineration is discharged through the chimney after denitrification and heat exchange, and the dust removal and purification are carried out. The ash generated by the combustion enters the reloading kiln and is calcined to make cement. There is no ash residue in the whole process, and the harmless treatment of waste liquid is achieved.

Domestic typical performance:

Feixian Yizhou Cement Hazardous Waste Cement Kiln Co-disposal Project

Shandong Donghua Cement Hazardous Waste Cement Kiln Co-disposal Project

Incineration system for hazardous waste liquid

Viscous waste liquid spray test

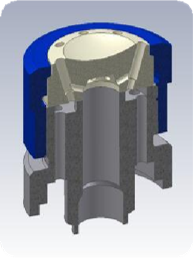

Burner internal structure