Solid alternative fuel system is a technology that converts combustible solid waste into energy. Through single or combined processes such as pretreatment, impurity removal, crushing, screening, sorting, and molding, solid waste such as household/industrial waste, biomass, waste tires, and large waste is converted into high calorific value alternative fuels, achieving the conversion of waste into energy. This technology not only solves the problem of traditional fossil fuel shortages, but also promotes the recycling of resources, meeting the challenges brought by global energy consumption, population growth, and accelerated urbanization.

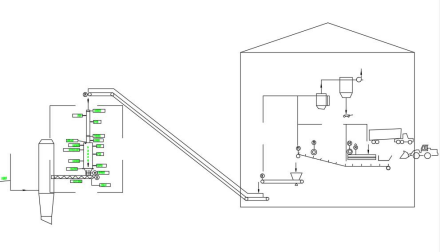

The solid alternative fuel (RDF) preparation system for household/industrial waste mainly targets high calorific value industrial solid waste such as waste fabrics, waste plastics, leather scraps, etc. By crushing, sorting, and forming processes, household waste is converted into high-quality alternative fuels, ultimately resulting in high calorific value alternative fuels (RDF) with a particle size of 98% less than 30-80mm.

The biomass solid alternative fuel (RDF) preparation system utilizes materials such as straw, tree branches, and bark to separate metal materials through crushing and magnetic separation devices. Combustible materials are then compressed into biomass alternative fuels through a compaction mechanism. RDF fuel formed from biomass straw and other materials has a calorific value of approximately 3000-3300kcal/kg. The combustion ash can be concentrated to produce potassium fertilizer, achieving zero emissions.

The solid alternative fuel (TDF) preparation system for waste tires first extracts the sidewall steel wires from the waste tires through a hydraulic wire drawing machine, and then processes them through crushing, wire separation, efficient screening, fiber separation, and magnetic separator to produce rubber blocks, rubber powder, and can also be mixed with other RDFs to significantly increase the calorific value.

The RDF (Large Waste Alternative Fuel) preparation system also converts large waste into alternative fuel through crushing, sorting, and forming processes.

The technical advantages of these systems include intelligent operation and maintenance systems, equipment made of high-strength and wear-resistant materials, and customized production line services, ensuring safe, efficient, and reliable operation. Solid alternative fuels, as a renewable energy source, have risen to the fourth largest energy source in various industrial kilns, such as cement kilns and fluidized beds, and can be safely processed under high-temperature processes without producing any residues