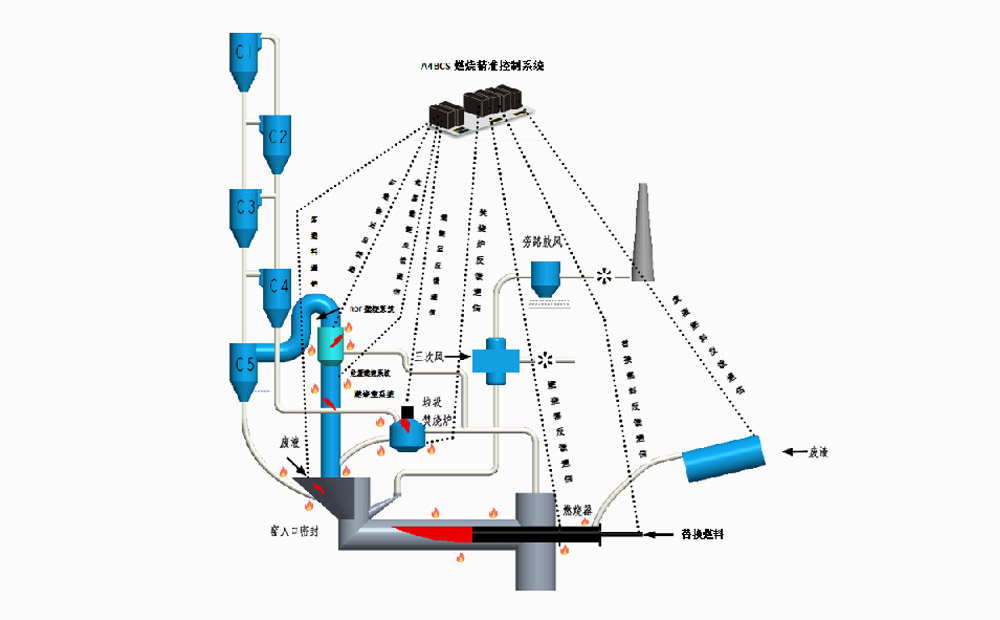

The precise control system for fuel combustion is a comprehensive system aimed at ensuring that the energy released by fuel combustion in the boiler furnace can meet the needs of the load, while maintaining a reasonable ratio of fuel and air, and balancing the flue gas and induced draft generated by combustion to ensure safe and economical operation of the boiler. This system usually consists of the following parts:

Burning station:

Including the main burner (adopting a diffusion structure, equipped with a swirl stabilizer with a DC section), fuel control valve group, operation control cabinet, and combustion air system.

The main burner body adopts a diffusion structure and is equipped with a swirl stabilizer with a DC section to enhance combustion efficiency. The ignition device adopts direct ignition method and selects high-energy ignition device with signal feedback. The flame detection device consists of a flame monitor, shielded cable, and processor, used to detect the flame of the burner.

The fuel control valve group includes manual shut-off valves, fuel quick shut-off valves, relief valves, fuel regulating valves, and pressure and flow detection devices to ensure safety.

The operation control cabinet is used for on-site ignition operation, controlling the opening and closing of the quick disconnect valve, on-site display of the fire detection processor, and the connection between DCS and on-site instruments.

The combustion air system consists of air, blower, air filter, valve and pipeline, etc., providing suitable combustion air for the burner.

Control system:

In order to achieve and complete the automatic control function of the drying system combustion station, the software and hardware parts of the control system have been specially designed.

In terms of hardware, it includes detection instruments, flame monitors, isolation units inside control cabinets, and DCS control centers.

Various detection devices on site will send the detection signals to the DCS redundant controller through the input/output isolation unit in the control cabinet for logical operation, adjustment, etc.

In addition, with the development of technology, intelligent combustion control management systems such as EBMS have been developed, using pulse combustion control algorithms and pure oxygen combustion technology to achieve coordinated optimization of multiple burners, ensuring balanced operation of each burner, improving operational quality and economy, while achieving safety controllable functions such as safety limiting, error handling, self-healing control, and intelligent voice alarm, greatly improving production safety